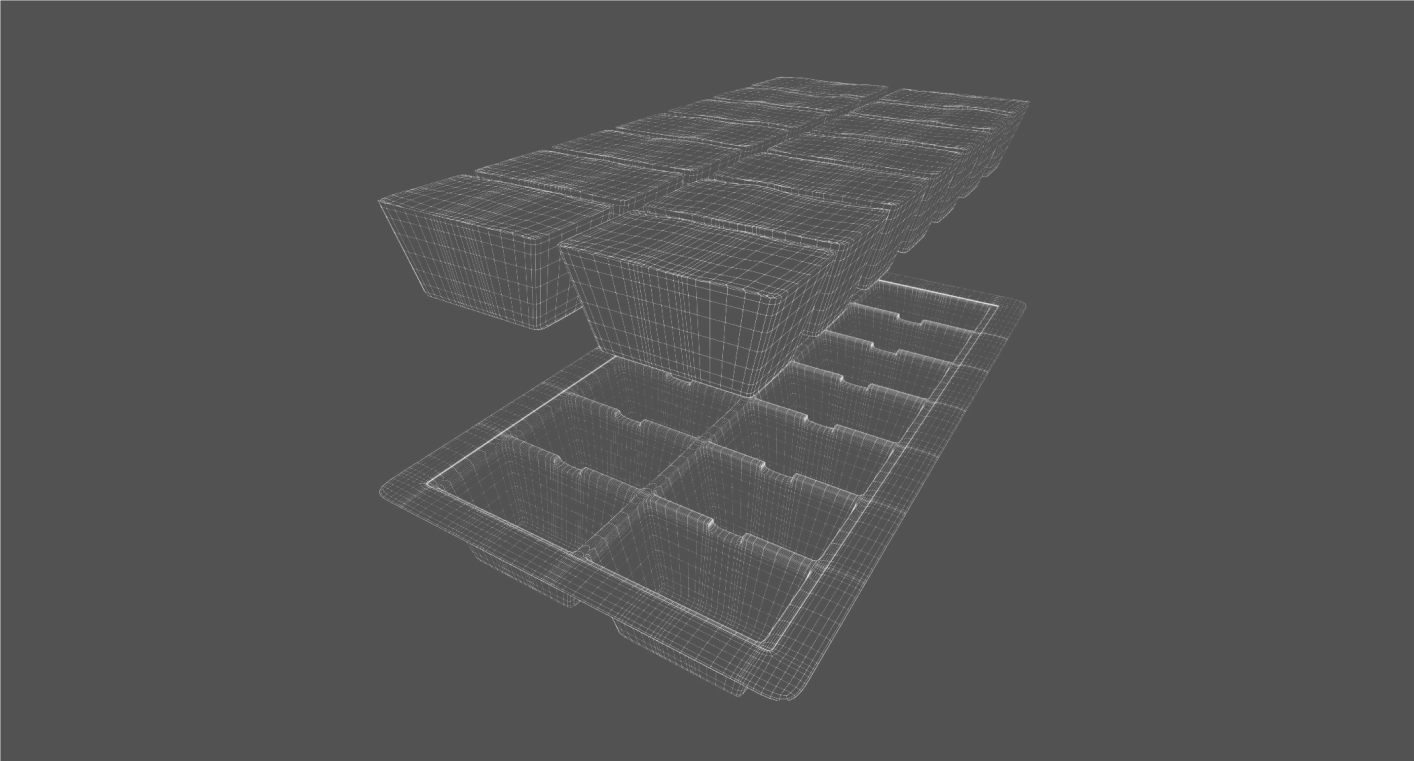

Why use space-saving stacks & nest trays or pallets

The space-saving stacks & nest trays are indicated when a sturdy structure is required, but at the same time, a significant saving of space dedicated to the storage of the same is desired.

Functional features

These trays can take up 50% less space when stacked and once they are rotated (180° or 90° depending on the models) they become self-supporting trays in all respects, with the usual characteristics of robustness, load capacity and suitability for automation.

Models of space-saving stacks & nest trays

Here is an overview of the main models of space-saving freestanding handling trays

Gamma

Self-stacking tray after 180° rotation, characterized by simple seats.

Suitable for handling pieces that do not require customized seats.

Suitable for handling pieces that do not require customized seats.

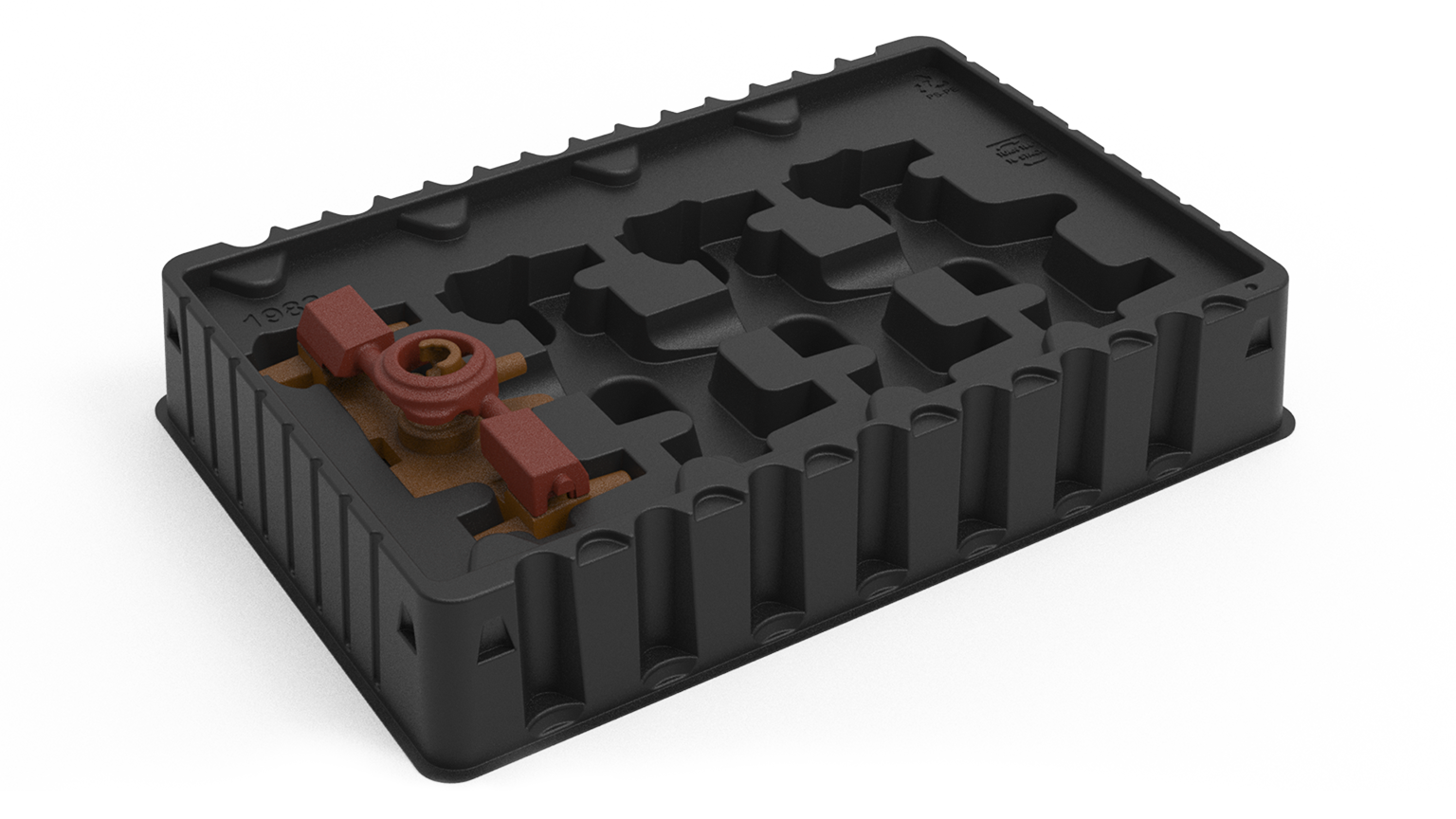

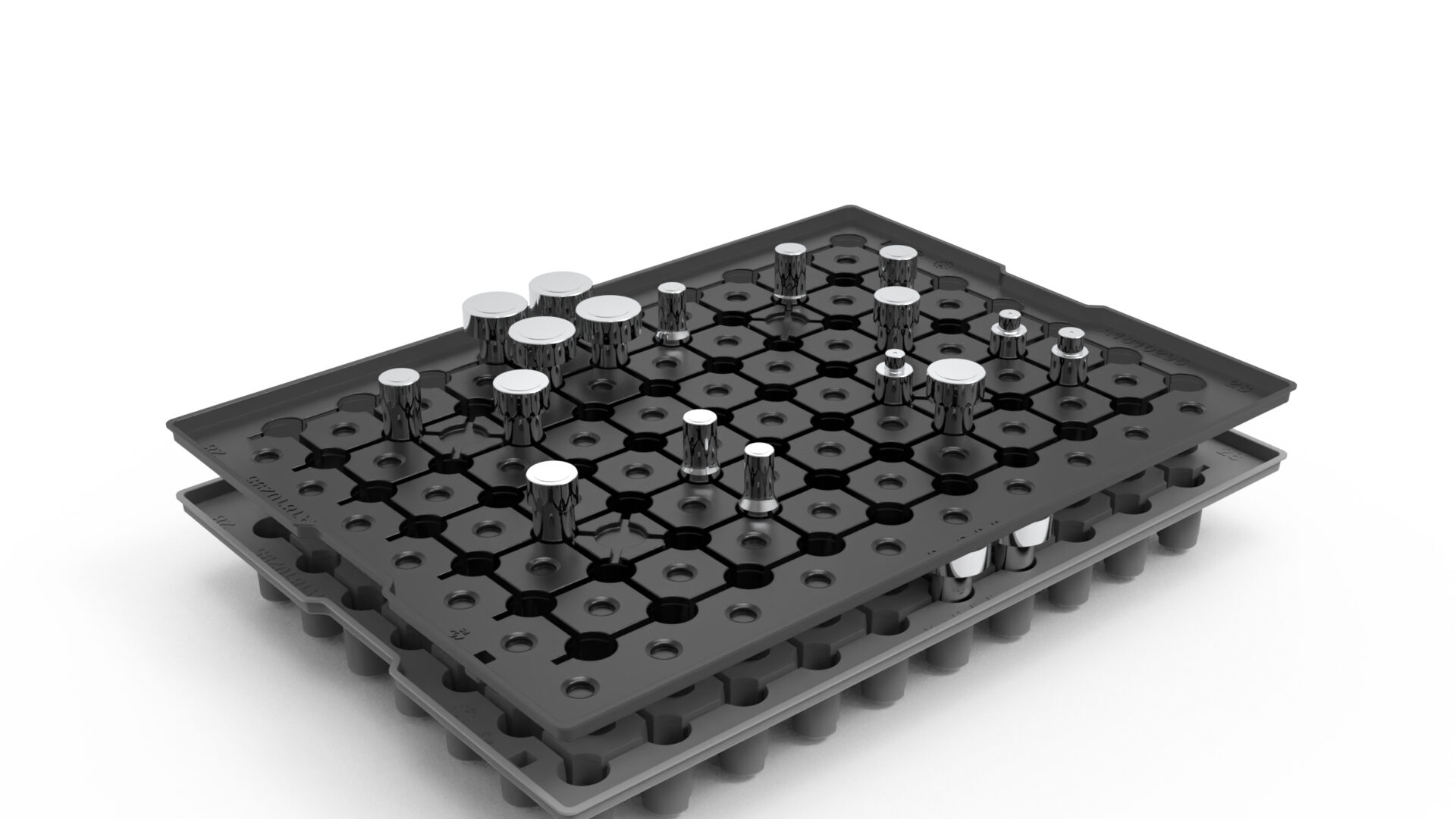

Delta

Self-stacking tray after 180° rotation.

This tray has asymmetrical seats and is provided with counter seats designed to constrain the tray above. It has precision seats and the load distribution is uniform as it is equipped with multiple support points.

Suitable for heavy pieces, ideal for large formats.

This tray has asymmetrical seats and is provided with counter seats designed to constrain the tray above. It has precision seats and the load distribution is uniform as it is equipped with multiple support points.

Suitable for heavy pieces, ideal for large formats.

Kappa

Self-stacking tray after 180° rotation.

It is equipped with asymmetrical feet to allow the overlapping of the trays, and with central feet to support heavy weights.

The weight of the tray is supported by the self-supporting edge. Equipped with handles for manual grip. Recommended for manual handling.

It is equipped with asymmetrical feet to allow the overlapping of the trays, and with central feet to support heavy weights.

The weight of the tray is supported by the self-supporting edge. Equipped with handles for manual grip. Recommended for manual handling.

Sigma

Self-stacking tray after 180° rotation.

The Sigma tray has a self-supporting edge and is self-centring.

This tray is very suitable for automation, with customizable and high-precision seats. Conceived in such a way as to possibly change the thickness of the material without affecting the size of the seats.

The Sigma tray has a self-supporting edge and is self-centring.

This tray is very suitable for automation, with customizable and high-precision seats. Conceived in such a way as to possibly change the thickness of the material without affecting the size of the seats.

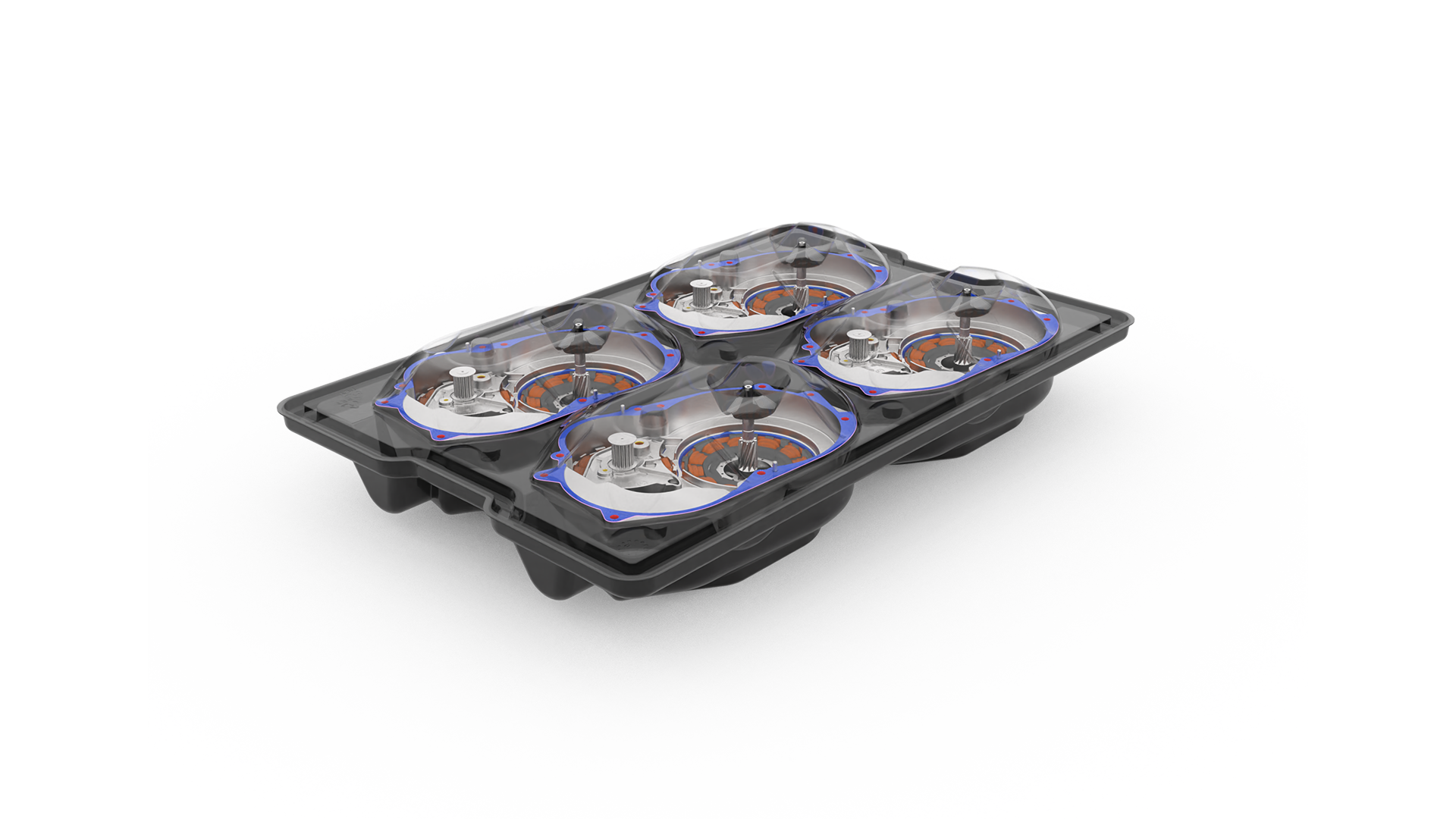

Iota

A freestanding container consisting of tray and lid. In addition to being load-bearing, the lid can also have the function of orienting the piece stored internally in the right position.

Suitable for movements that require cleaning of the pieces. Suitable for industrial automation.

Suitable for movements that require cleaning of the pieces. Suitable for industrial automation.

Eclipse

Self-supporting square tray after 90° rotation.

Suitable for automation, with customizable locations.

The structure is load-bearing only in the central part.

Suitable for automation, with customizable locations.

The structure is load-bearing only in the central part.

Cosmo

Self-supporting tray after a 180° rotation. Suitable for manual handling of products during processing or shipping and excellent for use in automated production lines. Particularly recommended for delicate products and for optimizing the space to accommodate items of various sizes. Specifically designed for the cosmetics, beauty, and medical sectors.

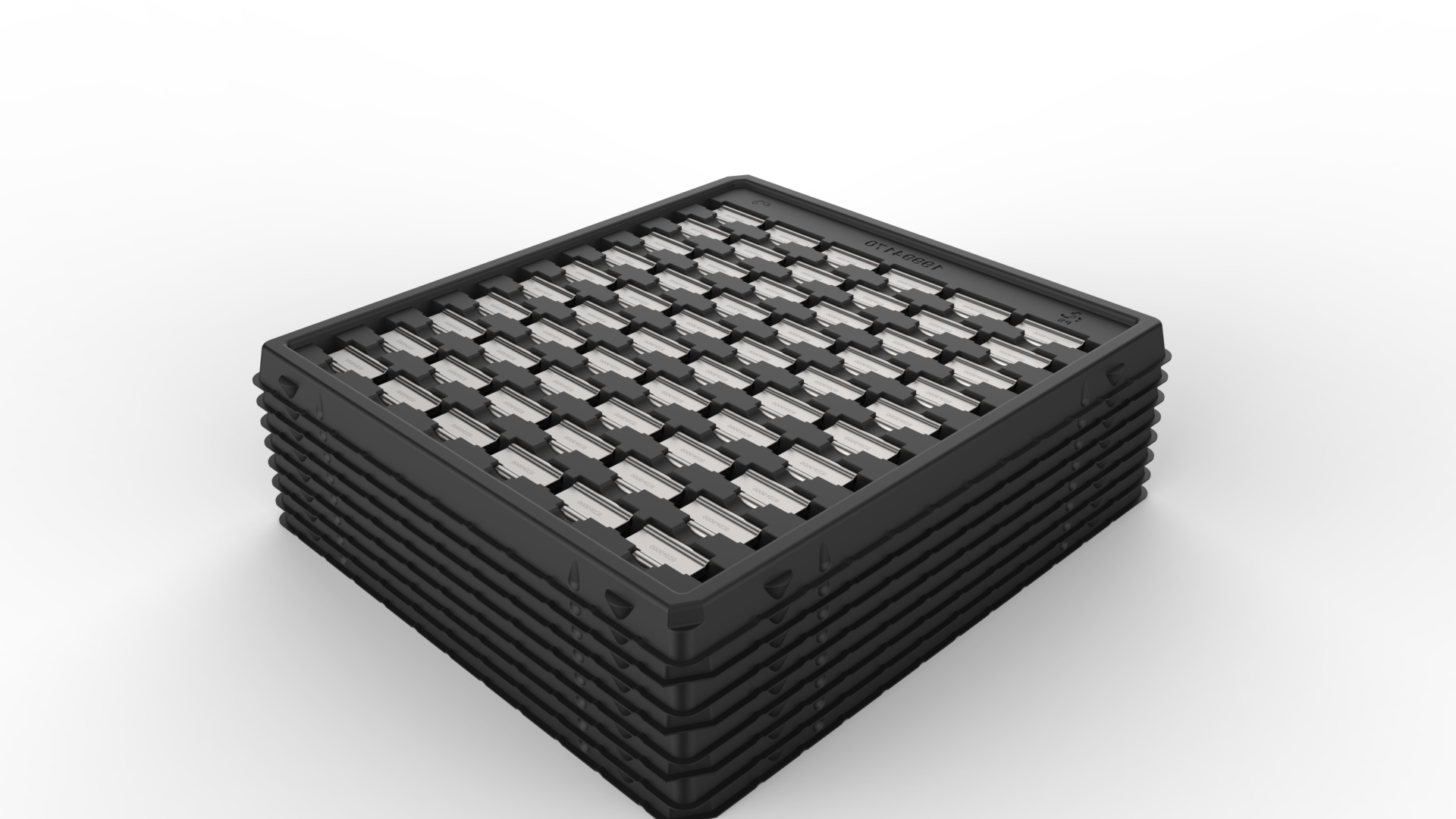

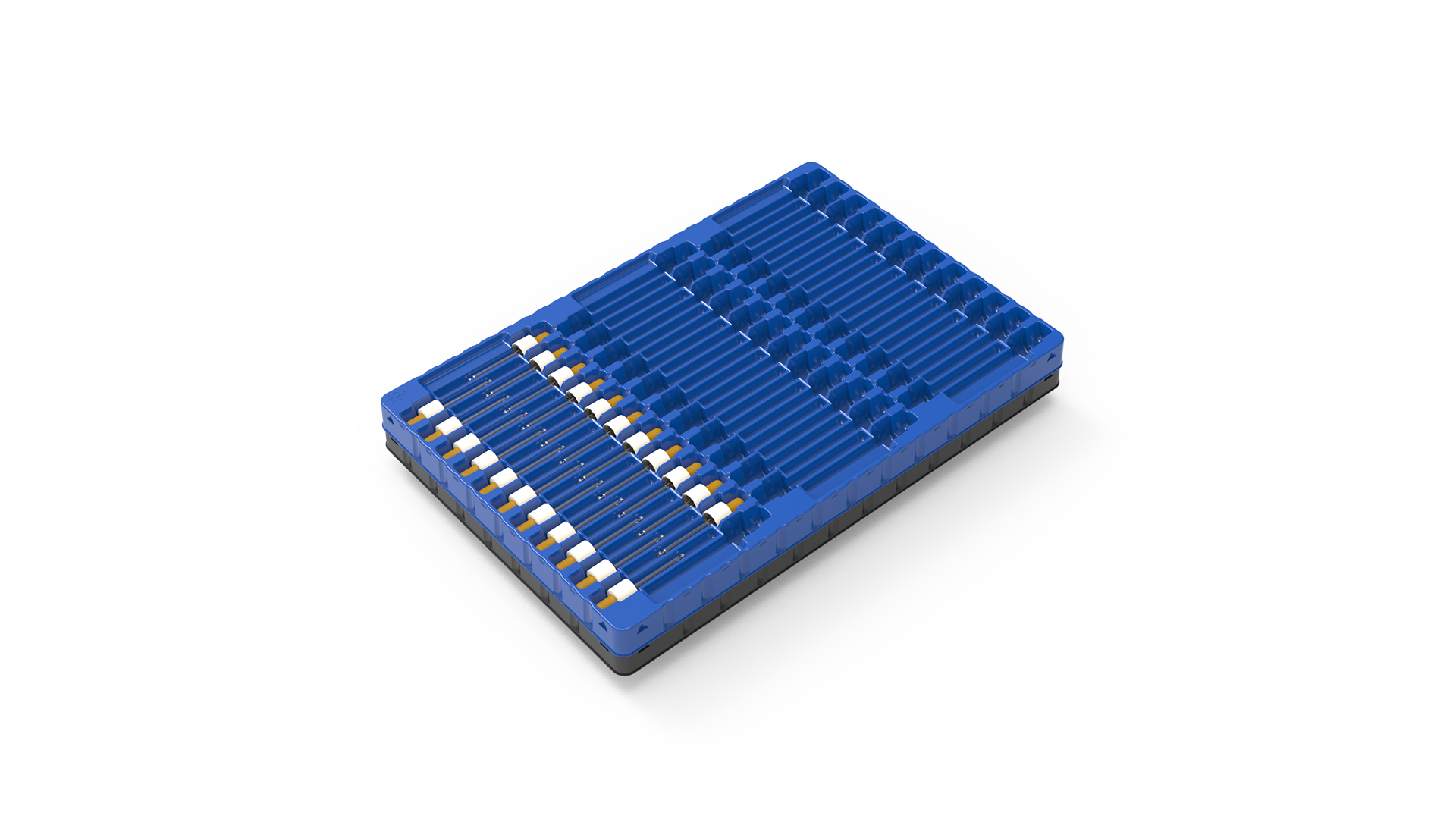

Rho

Self-supporting tray after 180° rotation.

Suitable for small cylindrical parts. It has a capillary load distribution and makes good use of the spaces both inside the tray and in height when the trays are stacked.

Suitable for small cylindrical parts. It has a capillary load distribution and makes good use of the spaces both inside the tray and in height when the trays are stacked.

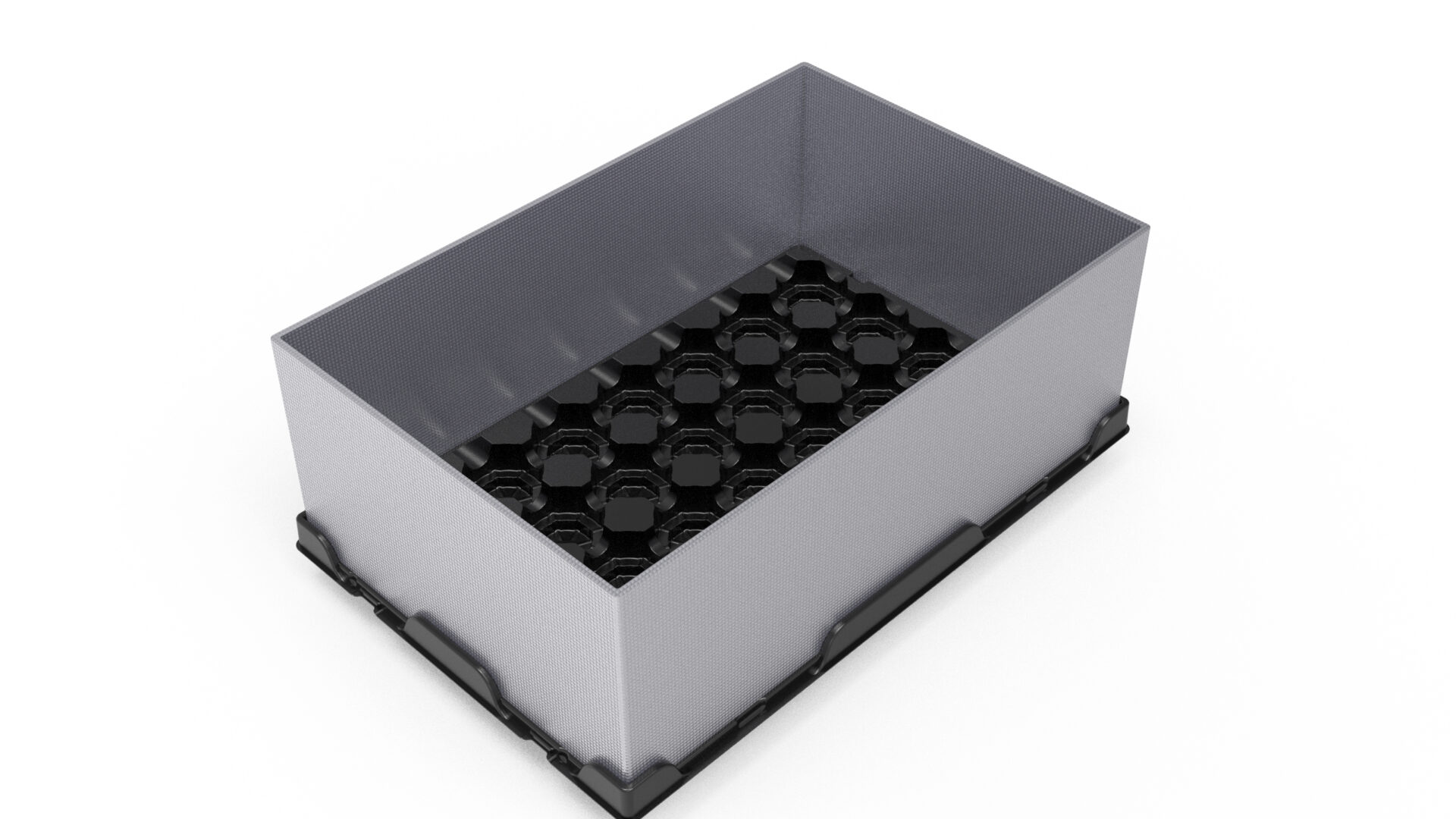

Zeta

Modular container composed of a thermoformed base and wall in alveolar PP. The seats of the base and the height of the wall are customizable.

This solution is suitable for pieces with high heights or for families of similar pieces but with variable heights.

The container is ideal for the clean handling of the pieces. Stable stacks of considerable height can be formed complemented by a top lid.

It does not require further packaging.

This solution is suitable for pieces with high heights or for families of similar pieces but with variable heights.

The container is ideal for the clean handling of the pieces. Stable stacks of considerable height can be formed complemented by a top lid.

It does not require further packaging.

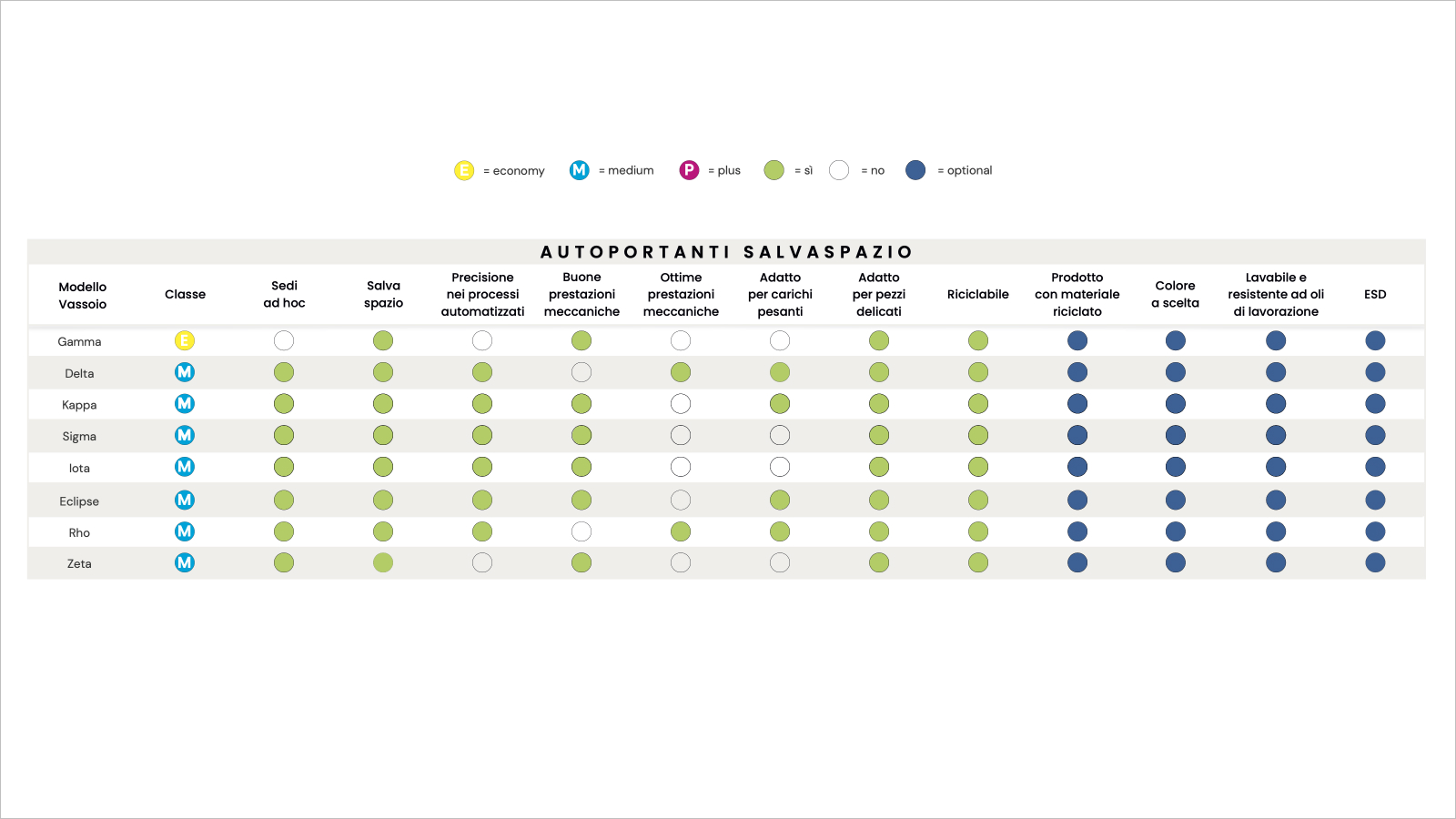

Usage

Comparative table of space-saving freestanding models

Main industrial sectors

We design and manufacture industrial trays and pallets for various sectors including: