Why use self-stacking trays or pallets

The self-stacking trays are indicated for their sturdiness and precision. Their shape is suitable for heavy loads and is designed to improve the accuracy and stability of the stack under load.

Functional features

Equipped with self-supporting edges, they can be self-centring and equipped with elements for interfacing with the automation.

Some models are equipped with undercut elements that act as supports for the overlap, while others have central feet, customizable seats and high precision. Several models feature integral perimeter closure which guarantees perfect cleaning of the pieces and high stacking precision.

Models of self-stacking trays

Here is an overview of the main models of freestanding handling trays

Duplo

The boxed structure ensures high load capacities, excellent dimensional stability, flatness and the possibility of using the seats on both sides.

Highly recommended for handling on robotic lines and for transporting heavy components.

Positioned directly on pallets, the Duplo tray guarantees precise, solid and safe stacking.

Lambda

In the packaging and shipping of products in cardboard boxes, Alfa allows for ordering and cleaning of the pieces as well as greater speed in the packaging phases.

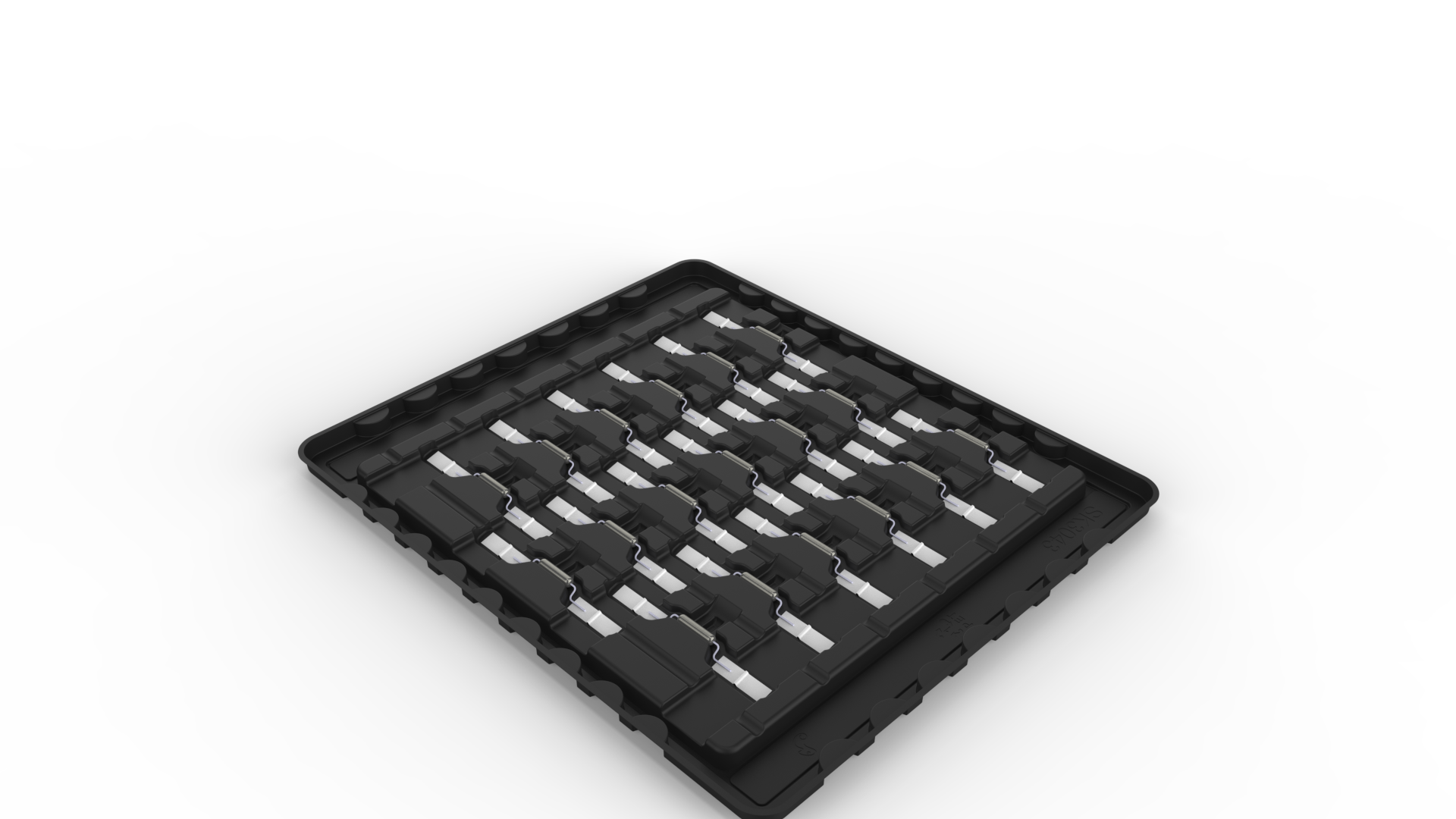

Omega

It features undercut elements that act as supports for the overlap.

This tray is very suitable for automation, with customizable and high-precision seats.

Suitable for handling light pieces.

The automation recognizes the correct positioning of the tray through the rounded corner.

Tau

The locations are customizable and kind of high precision, making this tray really suitable for automation.

Suitable for high loads.

Theta

It features undercut elements that act as supports for the overlap. Their shape is designed to improve the accuracy and stability of the stack under load.

This tray is very suitable for automation, with customizable and high precision seats; it is also equipped with elements for interfacing with automation.

Epsilon

Usage

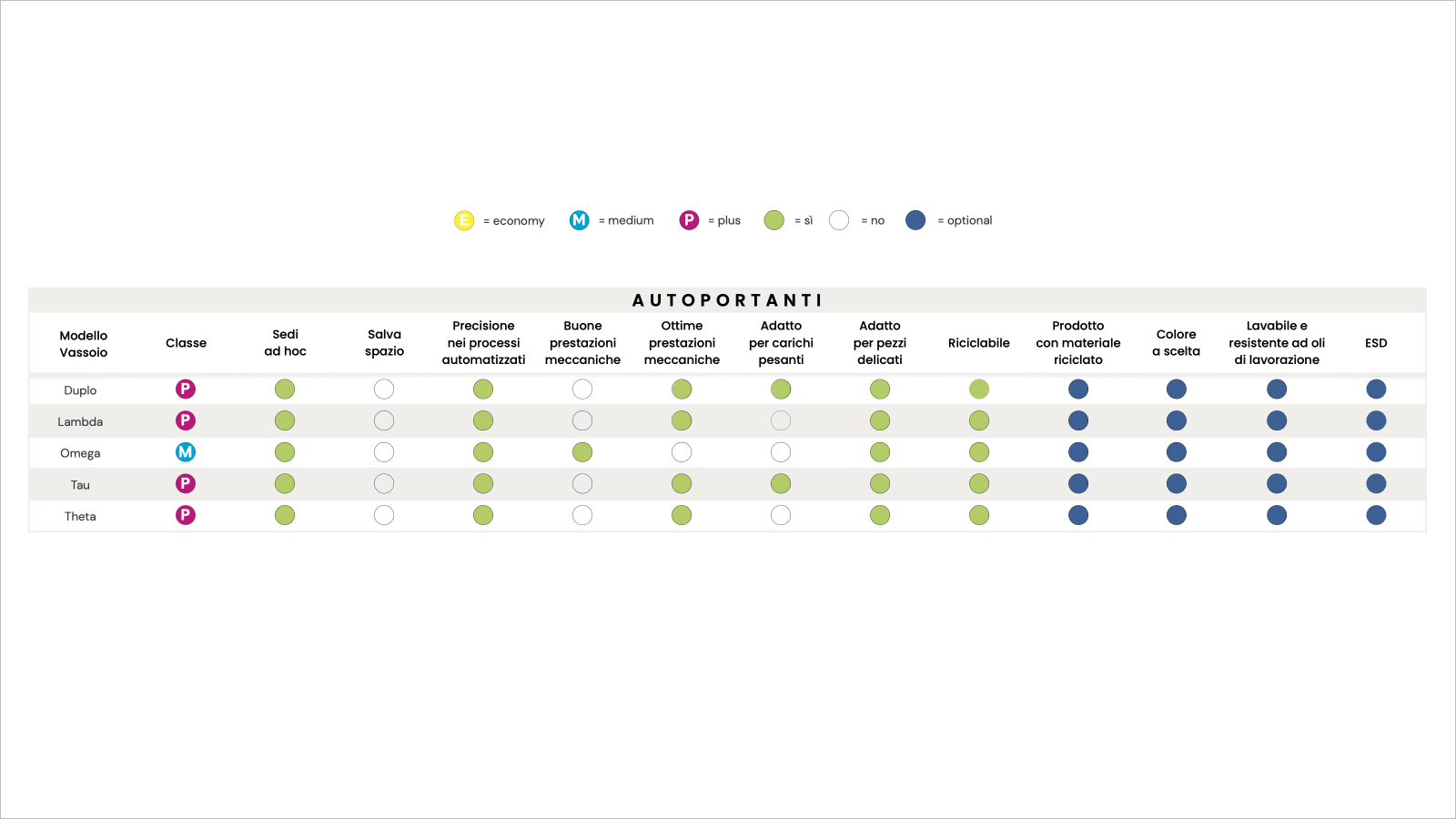

Comparative table of freestanding models

Main industrial sectors

We design and manufacture industrial trays and pallets for various sectors including: