Thermoforming is a plastic tranformation process. At first sight thermoforming seems to be simpler than injection moulding technology because it matches no problems related to plastic resins compounding.

However akwardness comes precisely from the heat shaping of a resin already manufactured thanks to various transformations such as extrusion, calendering or casting to convert plastic into a film or sheet.

The plastic memory of the material caused by tensions from inside, coming from the previous transformation process, involves non-uniform forming and film thickness out of control. The complexity in thermoforming process, as mentioned above, consists in standardisation of features and technical performances of the final product.

Accuracy in equipment design, vast experience in mold construction, manufacturing process and high quality control, allows to reach the fixed goal.

Thermoforming process

Thermoforming is a hot-deformation process that molds thermoplastic film or sheets on a mold. The shape of the mold is faithfully copied by suctioning out the air that remains between the film and the surface of the mold under low levels of vacuum (~0.5 mbar of final pressure).

In some vacuum machines, compressed air (at a pressure of up to 10 bar) is injected into a bell closed on the other side of the film to achieve greater fidelity of minute details and more uniform stretching. One of the intrinsic characteristics of the thermoforming process is that new material is never added; the quantity of material is predetermined and only deformed.

To obtain the most uniform stretching possible, suitably shaped counter-molds are often used to improve results at the most difficult points.

Thermoforming operations

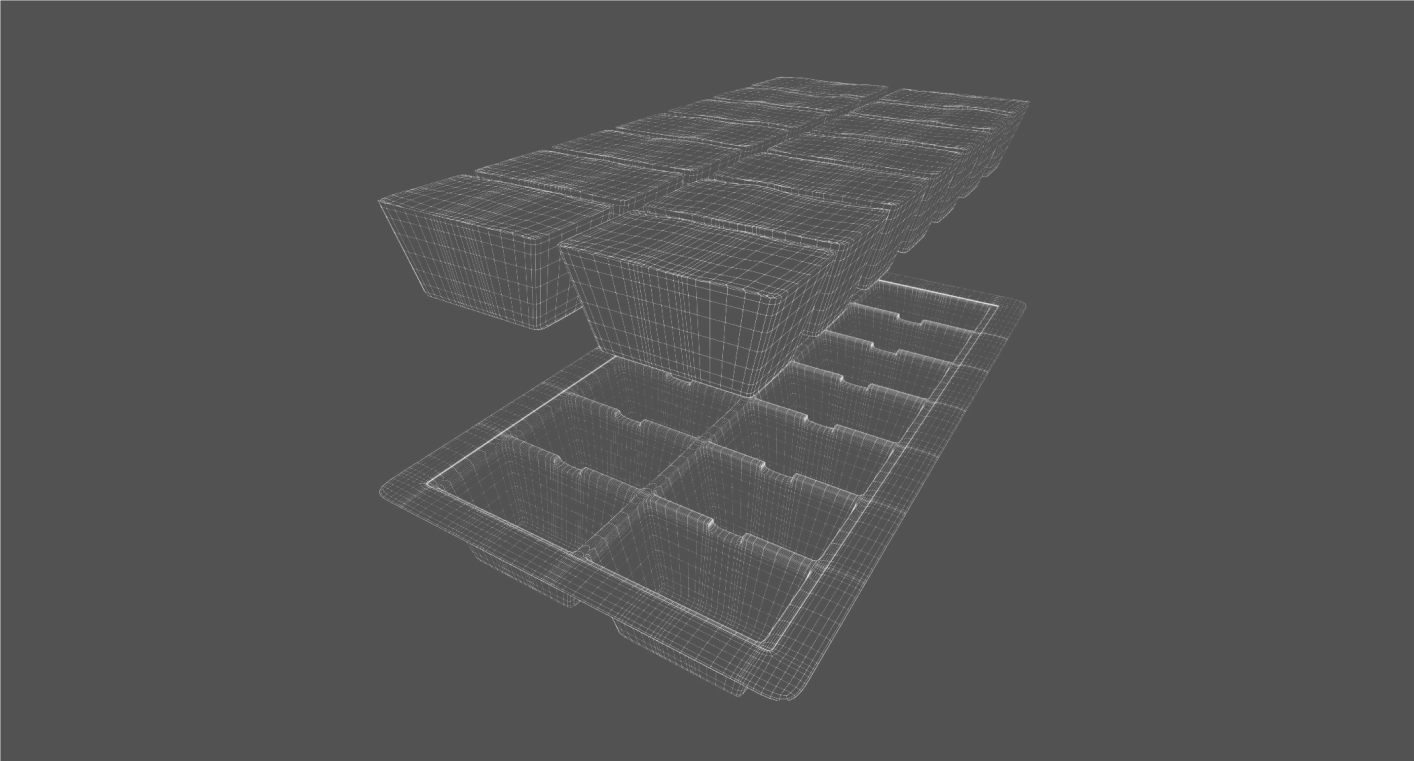

Molding by thermoforming is only the first step in making the final product. Starting from a film or sheet with defined physical dimensions, the thermoformed piece must be separated from the scrap, i.e., the excess material that is not part of the shape of the piece to be obtained.

In the case of the thin materials used to make light packaging, we proceed to punching using American type dies and presses.

For thick materials, on the other hand, we use milling cutters. Currently, we, almost exclusively, use numerical-control centers that are capable of performing complex cutting and drilling to meet the customer’s needs.

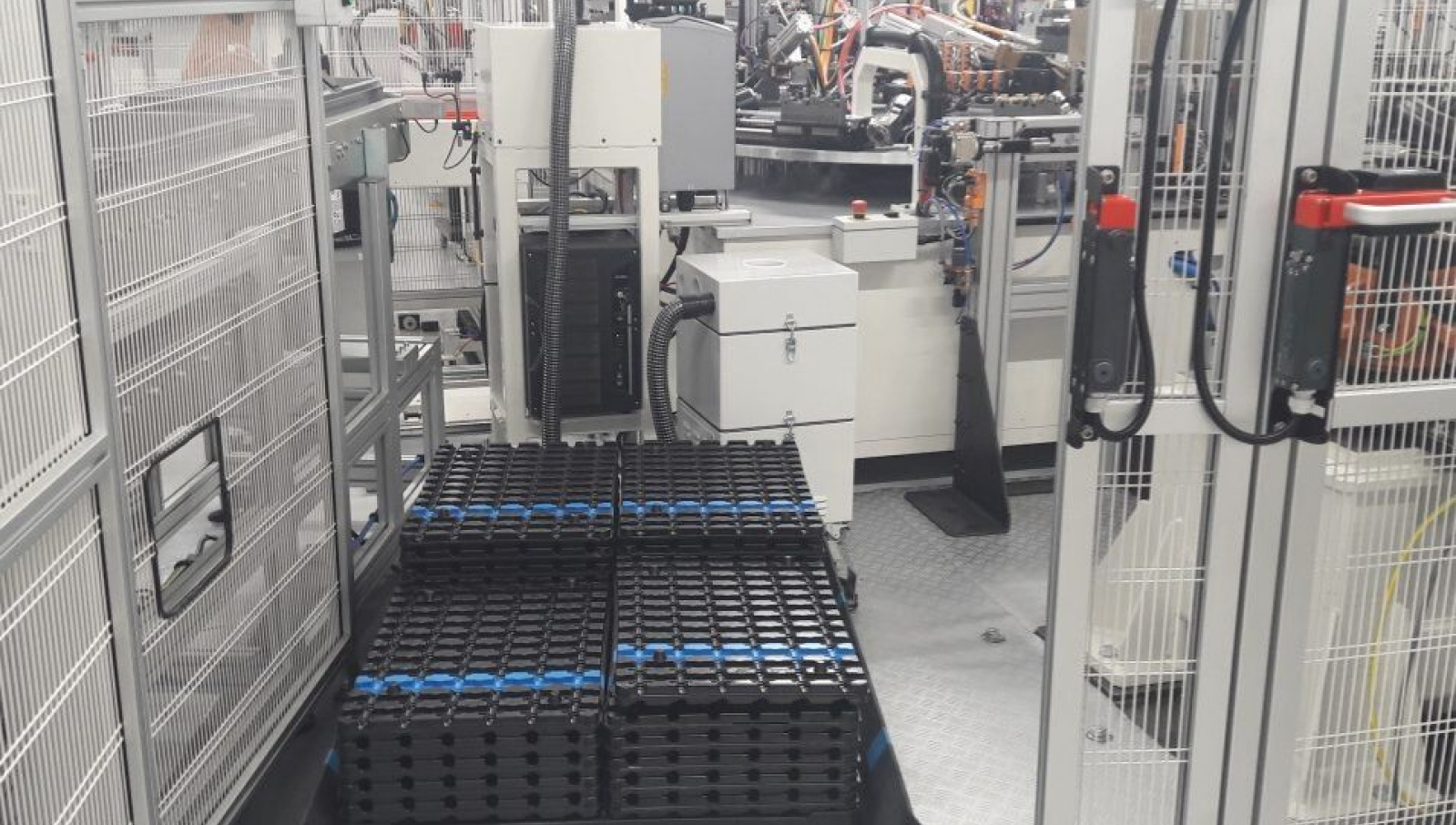

For the production of objects that must be robust and highly precise (such as pallets for robotized handling), we glue and weld 2 or more shells (i.e., single thermoformed pieces) specifically designed for the production of articles with box elements that significantly increase their strength.

We can perform any other work necessary to obtain the required product.

Le materie plastiche

Only some thermoplastic materials can be transformed into films and sheets suitable for thermoforming.

- PS: polystyrene (and its derivatives EPS, BOPS and ABS)

- PVC: polyvinyl chloride

- PET: polyethylene terephthalate (in its various formulations: PET-A, PET-G, PET-C)

- PP: polypropylene

- PC: polycarbonate

- Mixed compounds (Koblend, Gerpack, etc.)

Depending on the application and the cost, different materials can be used that determine the characteristics of the thermoformed product and the processes needed to make it.

Polyethylene terephthalate

High Density Polyethylene

Vinil or Polyvinil Chloride

Low Density Polyethylene

Polypropylene

Polystryrene

All other resins: Multi-layered plastic