In the context of integrated logistics, thermoforming takes on importance in the supply chain due to the wide versatility it offers to solutions for industrial handling.

The optimization cycle

In material logistics, that is to say, in internal and external handling, thermoformed products are not just a subsidiary tool for production, but are essential for obtaining valid results in a planned process.

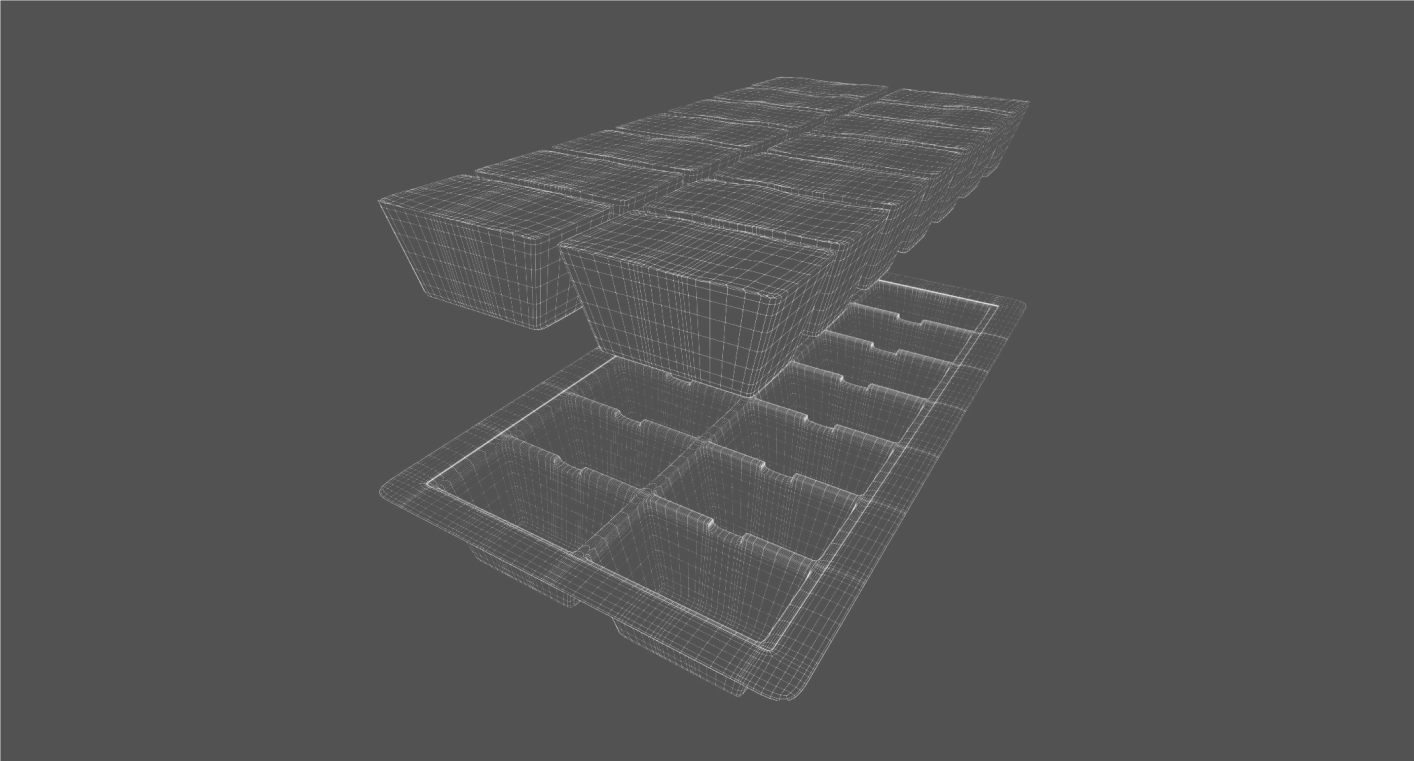

The arrangement of pieces

An accurate design during the devising phase allows optimal organization of the tray contents and the best arrangement of the pieces for intermediate manipulations during the production cycle.

The use of handling solutions such as trays or pallets to contain the pieces allows you to identify ex-ante the number of pieces being processed and eliminates the problem of counting the number of items to be inserted in the boxes: the thermoformed mold houses a predetermined number of pieces and there is no possibility of error. In the same way, the customer or the subcontractor who receives the pieces housed in trays will not need any numerical control: an empty compartment will immediately highlight any shortcomings.

Cleaning of pieces and semi-finished products

Ellepack’s commitment to finding appropriate solutions has guaranteed high standards of cleanliness and hygiene for years. Fundamental is the study of correct packaging in relation to the company sector, the type of production line, the processes applied, the materials used and the degree of finish of the product. Furthermore, thermoforming trays with a specially studied design prevent the proliferation of bacteria in the accumulation points of industrial workstations.

Mechanical processing requires oily emulsions, washing, degreasing of metals with chemical solvents and further applications of oily materials; these phases are all particularly sensitive to dust that cause damage if the piece is not housed in suitable containers. The use of trays specifically designed to keep metals clean helps to reduce possible damage.

A particular case is the replacement of the cardboard packaging with the thermoforming tray; this allows to eliminate the cellulose and therefore the particles that adhere to the surface of the particularly receptive pieces due to the treatments undergone. The plastic film produces a perfectly clean environment and, by not releasing any microparticles, keeps the piece unaltered, both in the intermediate phase and in the final phase of the logistic process. Furthermore, at Ellepack we produce thermoformed products in working environments that guarantee total cleaning of the tray, sometimes intended for food contact, and we are therefore able to guarantee an additional level of cleanliness for the products that will be handled.

Finally, it is worth mentioning the ESD antistatic thermoforming products, which thanks to the use of suitably treated polystyrene avoid the accumulation of electrostatic charges and the consequent attraction effect of dust.

Safety for production workers and staff

The handling of materials, whether manual or automated, involves a degree of risk for the safety of workers in carrying out work activities due to the movement of loads, first of all, the risk of falling material and the consequent danger for those operatives in the working area.

The use of modern handling solutions such as technical trays makes it possible to significantly reduce these episodes in comparison with situations where such devices are not used.

Protection of the pieces during the handling phases

Many of the artefacts that come out of the production cycles require protection during internal logistics operations and in the final delivery of the item. Protection is usually required by the intrinsic fragility of the product and the material it is made of (glass, for example) or by the need to safeguard the finishing (chrome plating, embossing, metallization) from any surface damage. In other cases, it is necessary to protect an electronic or electromechanical device from impacts that could compromise its operation.

The thermoformed containers offer these protection guarantees with some strong points:

- low volume and footprint

- easy to reuse

- intrinsic cleanliness

- total recyclability (eco friendly)

- special finishes (in cases of extreme care of the surface of the piece, they can be flocked, that is to say, treated with a “velvet” effect surface, offering maximum protection and comfort for the piece)

Through the most innovative tray thermoforming technologies, Ellepack ensures excellent protection at every stage of industrial automation processes: the customer is guaranteed impeccable conservation and protection of the components involved.

Integration with automated lines

We know how much automation and robotics are gaining ground in industrial processes, with different applications: cartesian robots, anthropomorphic arms, pick and place robots. Then the spectrum of processing is broad: ranging from palletising at the end of the series, to the enslavement of machine tools, to the various stages of mechanical processing. All these activities in place of the human process need spaces for gripping the workpiece and housing for the final or partial placement of the product. It can also be a packaging phase at the end of the production cycle, but in any case, it will always be a piece that will move from one place to another thanks to the intervention of the machine. In all these processes, the tray is very often the element that guarantees the proper functioning of the robotic line and even if it apparently plays a supporting role, it actually performs a fundamental task.

Ellepack has specialized in the production of trays for the automation lines where the precision in the design of the tray must guarantee:

- correct room for manoeuvre for the robot grippers;

- safe stacking of trays;

- easy unstacking of the same trays.

Each point and housing of the tray is designed and calibrated to avoid stops in the lines that would cause considerable damage in industrial production processes. In this way Ellepack finds itself working alongside system integrators to guarantee companies the best performance in automated processes.

Ellepack products integrate perfectly with any industrial equipment, allowing greater coordination in the phases of the production process.

Efficiency and waste reduction

Digitization and the adoption of lean manufacturing principles in production processes have

this, which today is commonly called smart factory, is the face taken by the modern manufacturing industry which adopts processes, in turn, referred to as smart manufacturing.

The adoption of thermoforming trays can be used by the smart factory to reduce waste due to incorrect optimization of workspaces.

The different and renewed man-machine interaction makes the employee a controller of the correct functioning of the system, partly removing him from the need to intervene as a pure operator. All this translates into the need to have tools available that can considerably reduce the material intervention of the person in the production process. The thermoformed tray fulfils, among other things, this specific need by acting as a “carrier” for the products during the processing cycle.

At this point, it is evident how the thermoformed tray, thanks to its function of multiple housing of the pieces, allows to better manage the physical spaces. The efficiency and effectiveness thus obtained, can be added to the order in the handling of the pieces consequently gaining rationalization of the various processing phases; this is a benefit for an advanced and complex production system in its operation.

Optimization of spaces

Optimizing production spaces is a necessity of the modern digital factory oriented to results and waste reduction. Ellepack design consultancy and thermoformed products respond proactively and decisively to the requests of the smart factory, generating value by reducing waste and increasing results.

Space optimization does not only concern the production process but also involves the design and management of goods storage: the area dedicated to the warehouse is in close connection with the production area, both in the phase prior to the manufacturing process and downstream of the process itself.

Establishing the configuration and orientation of a tray requires expert advice, in-depth analysis and a careful evaluation of the pros and cons of each alternative. This is essential to ensure maximum efficiency of the system: optimization of the storage area through the use of thermoformed products takes place already in the design phase, being able to establish ex-ante the ideal solution for saving and proper space management.

The 180 ° rotatable self-supporting tray is a significant example of “space-saving” as it can reduce its volume by 40% when stored empty.

A customized solution

All the advantages offered by the introduction of the thermoformed product in the optimization of the production process are measurable and quantifiable. Ellepack’s experience in supporting companies wishing to optimize production offers projects that can be perfectly integrated into the planning of the production process aimed at increasing performance and skills.

It becomes necessary that the industrial or consumer product is designed together with its wrapping (packaging) and everything that will function as logistic support (such as the thermoformed tray). This coexistence of different aspects in the very first design phase ensures that logistics correctly perform its task of integrating processes with a view to efficiency and effectiveness, measurable thanks to predetermined indicators. This avoids making the mistake of reducing “packaging” to the last weak link in the chain.

Designing products for industrial handling

Discover our approach to design