Ellepack designs and manufactures thermoformed trays for the safe transport, handling, protection and positioning of pieces and parts for manual or automated processes, with thicknesses from 0.3 mm to 10 mm, designed to optimize the use of space and make transportation easier

Thermoformed handling trays are designed in different thicknesses depending on the peculiarities of the objects they will house: minimum thicknesses for disposable trays used for a single transport cycle or very thick for the cyclical reuse.

Ellepack offers handling trays for automated robotic lines where every tray is arranged on standard transport containers such as plastic Odette boxes, pallets, metal baskets, etc.

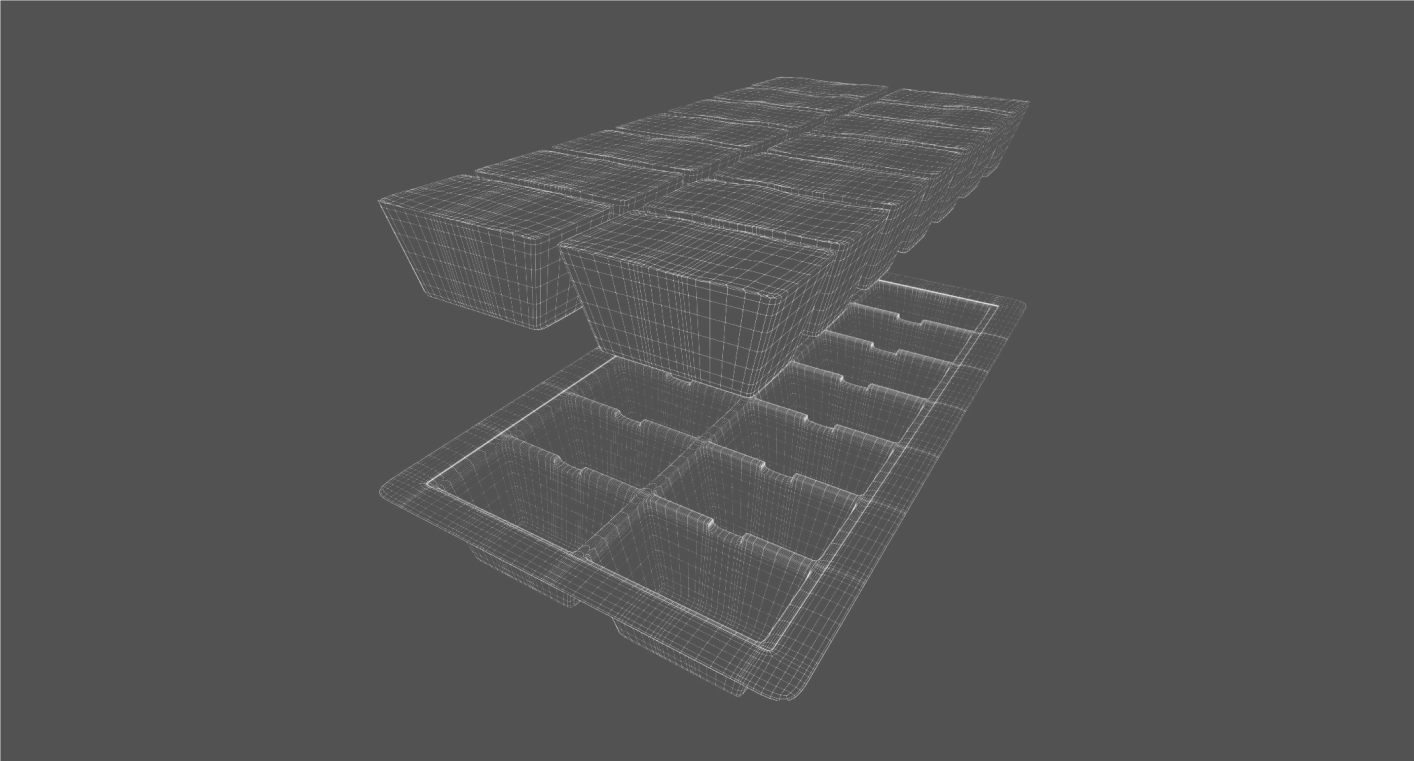

Each tray is designed according to the specific customer need, provided along with a deep consultation and support for its complete adaptation to the automated lines. The tray is also designed to allow both self-supporting stacking during the use and superimposition with space reduction when the process is over.

Handling trays suitable for all sizes, large and small.

The automatisation of industrial processes has given a boost in all the sectors of manufacturing industry. For this reason Ellepack aims to give an important contribution to Industry 4.0 by manufacturing trays focused on automated processes; in fact, every company needs to handle pieces during the process. Greater productivity can also be achieved through the orderly, clean and repeatable handling of pieces in order to reduce the number of manual stages.

These needs become of primary importance when the supply chain includes equipment working automatically and following production sequences that requires precision and repeatability.

Thermoformed trays provide several advantages over metal or plastic containers or metal or wood trays because they allow pieces to be placed quickly in the smallest space and are also light with an excellent resistance to liquids and oils.

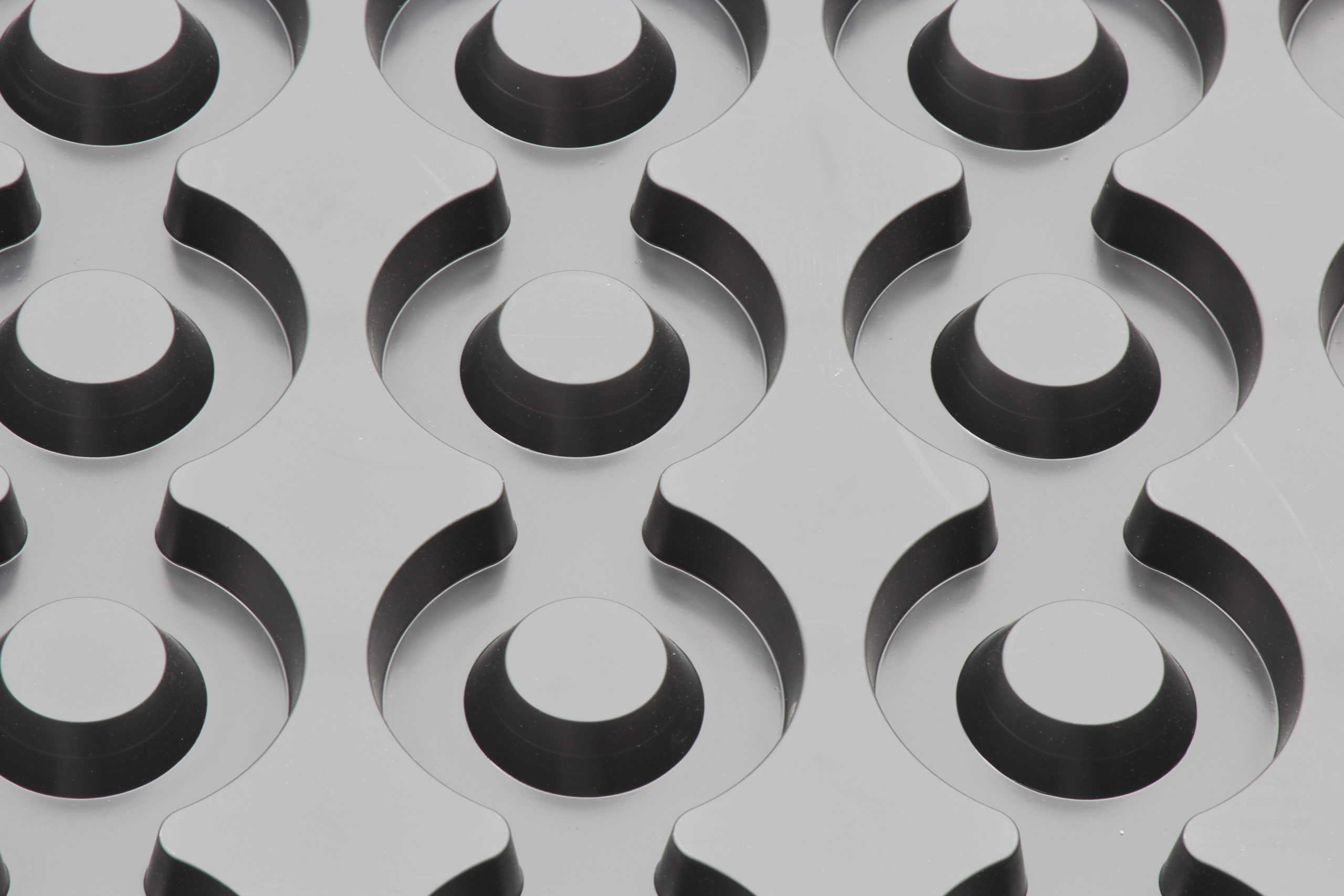

The large-scale production of item of every type and dimension has led to the design trays for different solutions both in an interleaving versions, for the simple separation of layers of pieces, and in self-supporting versions that support high loads according to the weight of the tray.