Industrial handling has acquired increasing importance in companies in recent years. Automated processes and the innovative trend towards digitalization have contributed to giving greater strength to the design of compatible and effective industrial handling systems to support and accelerate development towards the Smart Factory.

The internationalization of companies has also generated a very complex flow of goods, with a geographical coverage that today massively invests all continents. The shipment of goods must follow precise rules for the safeguarding of the products and of those involved in handling and transport, as well as those who will use the products. Therefore, handling goods is no longer a simple final appendix of the production process, but an integral and fundamental part of the value chain capable of generating advantages and increasing the intrinsic and perceived quality of what is handled.

Industrial logistics includes both manual handling and industrial automatic handling.

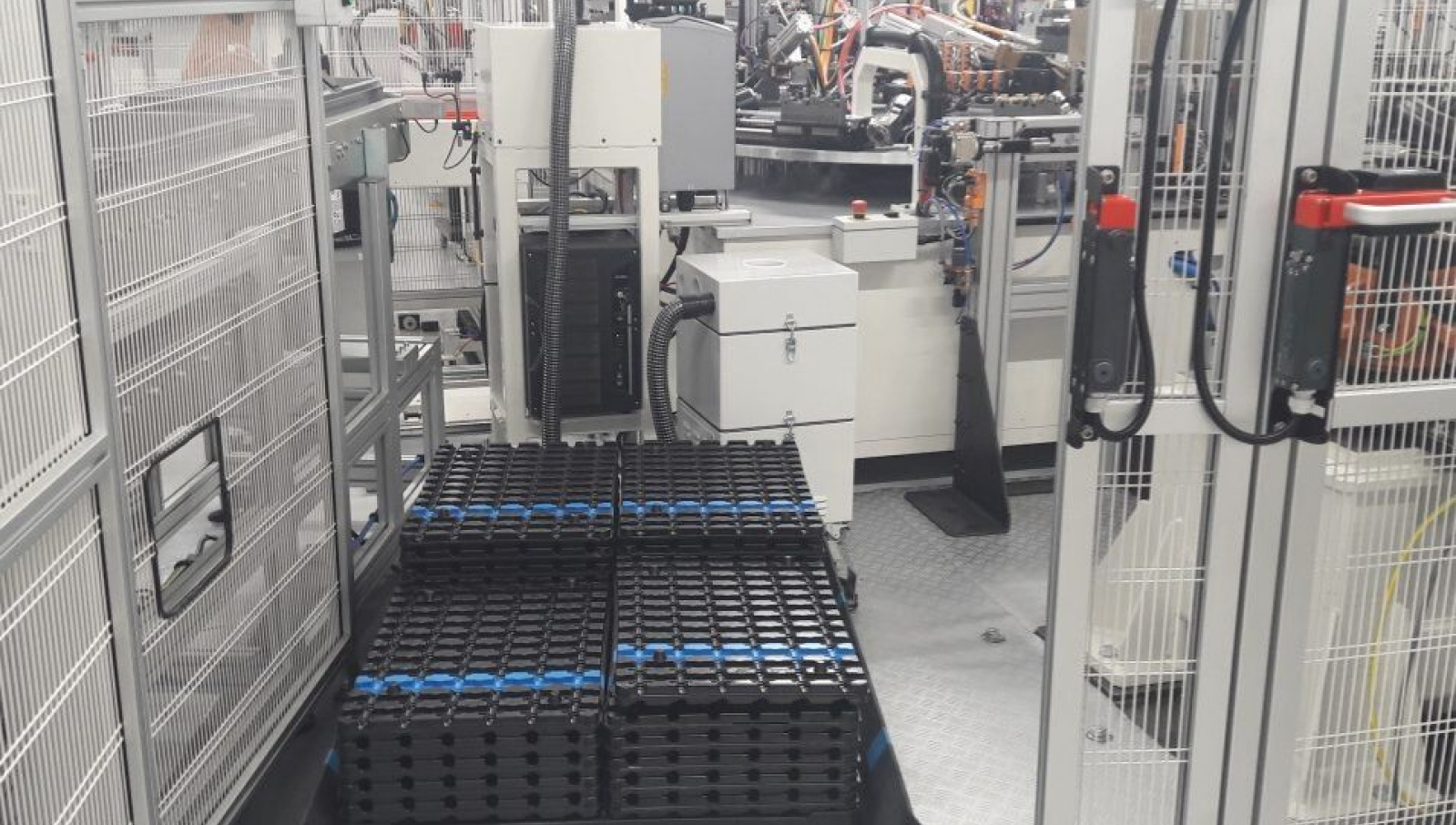

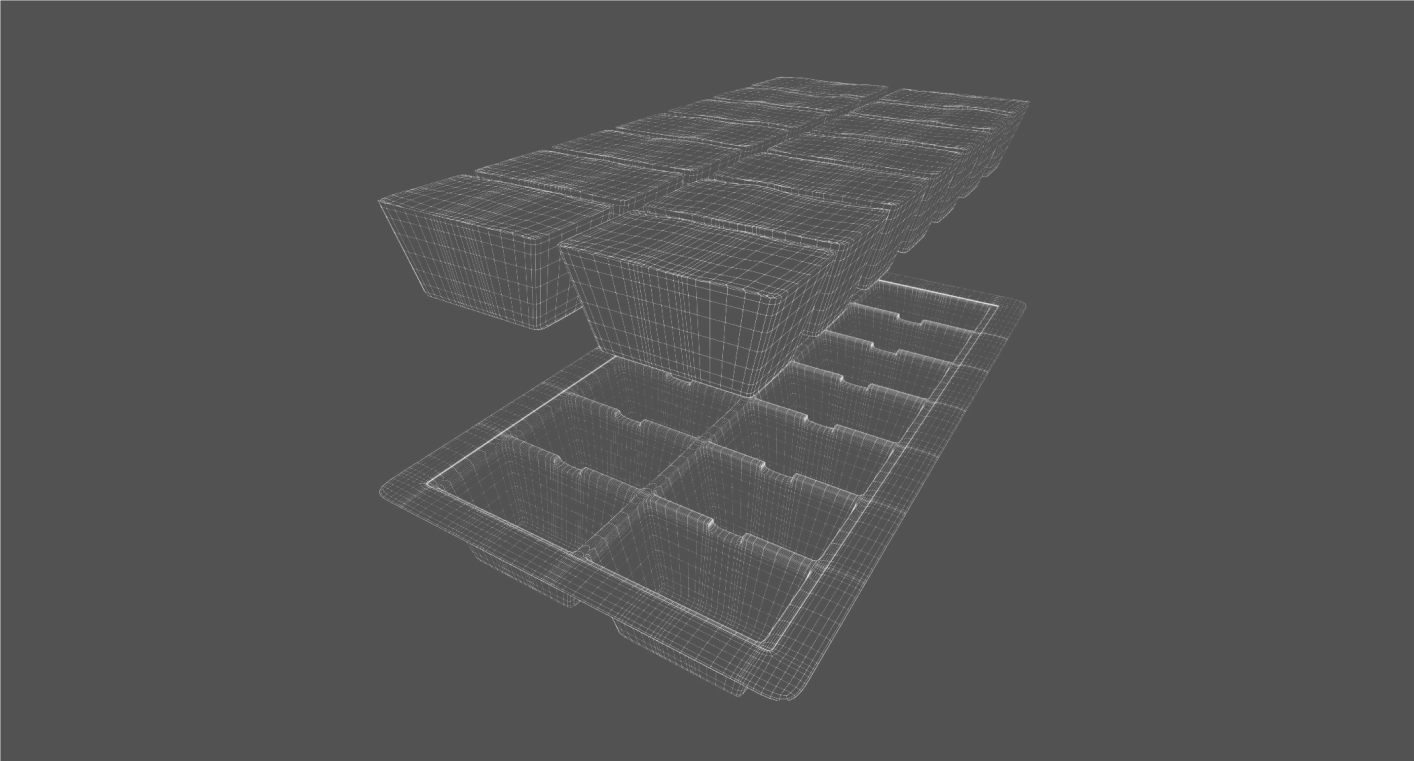

Industrial handling systems such as robotic islands and trolleys for industrial handling are two basic tools for logistics within the factory, but often require support such as the thermoforming tray capable of housing the pieces making the flow orderly and capable of guaranteeing the protection of the piece from possible breakages and damages.

A good industrial handling system must be able to guarantee the minimum waste of resources and the maximum yield of production performance. When correctly integrated into the automated industrial handling system, the workpiece tray constitutes a key element in the goods handling and storage process, being able to positively influence the development of logistics 4.0.

Optimizing material logistics

In our vision, profitable supply chain management is essential to ensure an efficient production process and optimal customer service.

“Moving a piece” of production from one place to another is today a fundamental activity that does not only concern the delivery of products, in a supplier-customer axis, but also and above all the different phases of processing the product itself, in a supplier-sub-supplier axis.

A significant example of the logistical complexity that binds the various players in the production chain is currently the automotive sector, where each component for the car undergoes different processes and transformations in places that are often very far from each other. Essential in these cases is the support of the thermoforming element to protect the pieces and ensure the integrity of the products. If we then go into the internal logistics of a plant, we find that the thermoforming product fulfils decisive functions in the handling of materials (material handling), both manual and automated.

Overall, the thermoformed product intervenes effectively in the three main areas of logistics: within the company (in-house), in external processes (outsource) and in the delivery of finished products (delivery).

In the same way, the thermoformed product guarantees optimization of cycle times and rationalization of the spaces in the storage of goods.

Designing thermoforming trays and containers

Although modern industry tries to standardize processes as much as possible, it sometimes faces the dilemma of having to handle a large number of items and components. Faced with similar situations, purchasing and stocking such a large number of trays of different shapes and sizes, each designed for a single item, can be an excessive burden.

To respond also to this eventuality, Ellepack has studied multifunctional trays capable of handling different items: the seat is designed with particular shapes able to adapt to more than one product, allowing it to be housed, without affecting the ability to constrain the piece and on transport protection.

There are many plastic materials available for thermoforming and susceptible to different treatments: this is why the thermoformed product is used in almost all manufacturing sectors. The thermoforming tray, therefore, represents an optimal solution for modern companies and, responding to different needs, offers multifunctional and scalable solutions in different production conditions.

Thanks to its experience in the design of solutions for industrial logistics, Ellepack offers solutions aimed at the needs of the modern manufacturing industry, taking advantage of the versatility of thermoforming as a lever for process optimization.

Overall, the thermoformed product intervenes effectively in the three main areas of logistics: within the company (in-house), in external processes (outsource) and in the delivery of finished products (delivery).

In the same way, the thermoformed product guarantees optimization of cycle times and a rationalization of the spaces in the storage of goods.

Trays end of life cycle: recovery and management

For reusable trays, if they are broken or at the end of their life, the collection and recovery service for end-of-life or exhausted trays is available: this is a free collection service, without having to bear the costs of disposal.

The service has been designed to activate a virtuous cycle of circular economy, for respect for the environment with a view to corporate sustainability.

For this reason, we bear the costs deriving from the analysis of the type of plastic of the trays (many times the customer does not know the type of plastic composing the trays), of the transport, of the cleaning cycle (the state of the trays is sometimes very critical) and of the grinding to obtain a second raw material suitable for reuse.

Vacuum thermoforming of resins

Thermoforming products are assuming increasing importance in modern industrial logistics and their usage is constantly growing. Shipping, internal handling of goods, temporary transfers of products, are complex activities that require simple and functional answers to achieve results in terms of process optimization and cost savings.

Thermoforming is a transformation process of plastic materials through the hot deformation of a raw material reduced to the state of film or plate.

Here we want to offer a brief overview of the process and machining available in Ellepack, also indicating the plastic materials used and their specific characteristics.